Frequently Asked Questions

How can I identify what Gorman-Rupp Industries pump I have?

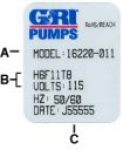

GRI pumps can be identified by the silver and blue label that is attached to each pump. The label includes the following:

- Model Number

(Every model number has the same format of 5 digits hyphen 3 digits.)

- Motor Information

- Date Code

(We use an internally generated Job Order Number.)

What is the difference between pumps with 2-wire and 3-wire leads?

2-wire lead

Two wires provide voltage to the pump. Speed of the pump can be changed by increasing or decreasing the voltage supplied.

3-wire lead

Three wires are required when the pump speed is controlled by a nominal 0-5v DC signal or a digital PWM signal. This is done through a control panel such as a computer or other control devices that is connected to the pump via the third wire. The 0-5v or PWM signal controls the speed of the pump, not the voltage supplied to the pump.

What is flooded suction?

Flooded suction occurs when the top of the fluid supply is above the pump inlet.

Read the "Flooded Suction" knowledge article and watch the "Do Not Run Dry!" video.

Read the "Flooded Suction" knowledge article and watch the "Do Not Run Dry!" video.

What is positive displacement?

This occurs when the fluid drawn into the pump is mechanically forced out of the pump.

What is self-priming?

A self-priming pump will evacuate the air inside it which allows the fluid to rise and enter the pump.

What is positive suction head and how does it affect my application?

If the fluid being pumped is located above the pump, this is called positive suction head.

Can the pump handle solid particles in the solution being pumped?

Generally, particles can prevent the valves from working and must be avoided.

How can I increase my bellows pump’s performance to meet flow and pressure requirements?

The performance of the pump can be increased by increasing the stroke length (displacement) or increasing the speed.

Are performance test reports available for my pump?

Yes, if you would like performance test reports for your pump, please contact GRI.

What is meant by duty cycle?

Duty cycle is the total amount of time the pump operates each day.

Do you have pumps on the shelf?

No, Gorman-Rupp Industries does not stock any pumps. We strictly build pumps to order.

Why is the ambient temperature important when selecting a pump?

High temperatures reduce the cooling ability and power of the motor, which will in turn affect the performance of the pump.

Why is the power supply important?

There are a couple of reasons why the power supply is important.

- Low voltage can reduce the motor power and the speed.

- High voltage can cause the motor to overheat.

The frequency must be correct (50 Hz, 60 Hz, DC) for the pump to run correctly.

Why is it necessary to know the size and length of tubing the pump will be connected to?

Long or restrictive tubing causes high pressure drags. This will reduce the pump flow and/or require more power.

My pump is noisier than usual when I turn it on. Why is this occurring?

There could be a mechanical problem with the pump or there could be a restriction in the suction tubing causing cavitation (noise).

Can my pump be repaired or do I have to replace the whole pump?

GRI offers repair kits and replacement parts for many of our product lines but not all. Some pumps simply have to be replaced completely in order to restore your system or machine to its original quality and performance levels.

For repair kit or parts, please contact GRI.

What are the warranty terms for a Gorman-Rupp Industries pump?

Please see GRI’s “Terms & Conditions of Sale.”